CPC Engineering - CPC COMPACT SOLUTION

In the Chemical, Petrochemical, and Oil and Gas industries, Hardware and Software obsolescence presents a constant challenge, which CPC Engineering addresses with its CPC Compact Solution. This Retrofit approach is designed to modernize Control Systems and improve the safety and efficiency of all types of industry plants.

What is our CPC Compact Solution

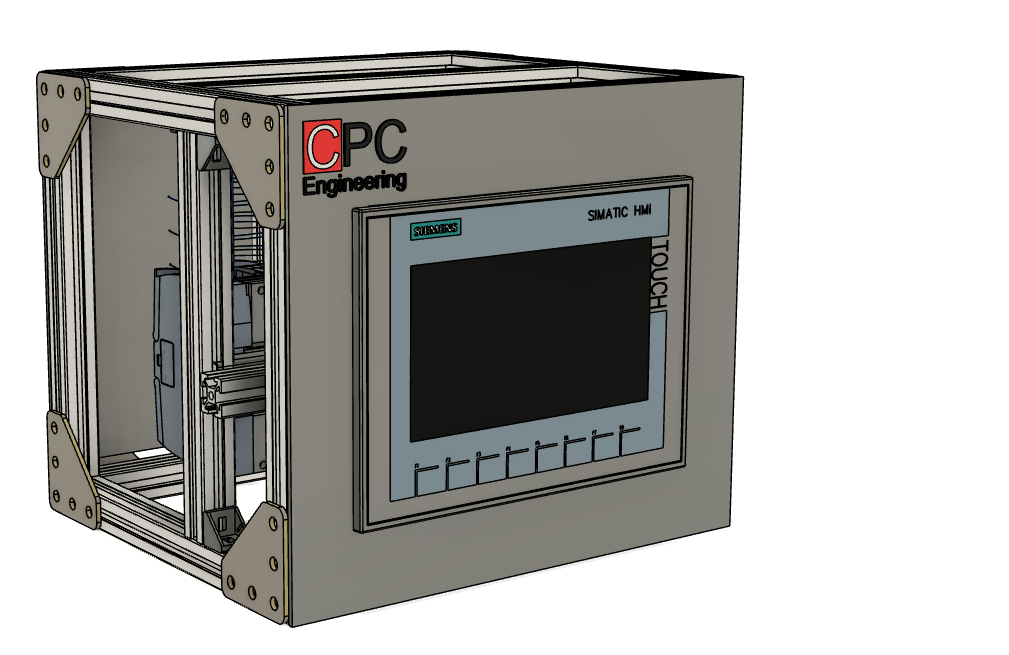

We offer a customized panel that integrates a PLC and an HMI. This system perfectly fits the original controller’s space, ensuring a smooth and efficient transition.

CPC has developed an intelligent Solution to replace obsolete controllers' Hardware and Software, focusing on "Complete 1-to-1 Functionality Migration" and "Full Integration with Existing Infrastructure".

CPC COMPACT SOLUTION

Front View

Side View

Rear View

Advantages

- Compact Design: Direct replacement without new panels required.

- Compatible Connections: Utilizes existing facilities without modifications.

- Minimal Modifications: Requires only minimal anchorage plate adaptation.

- Component Modernization: Transition to updated PLC and HMI devices, solving spare parts issues for obsolete controllers.

Flexibility

- Custom solution: Possibility of adaptation to functional safety requirements.

- Hardware: Ability to add as many I/O signals as desired.

- Software: Ability to incorporate new features upon client request.

- Communications: Integration possibility with high-level systems via Ethernet or RS-485 and RS-232 communication.

Benefits for our customers

- Significant reduction of over 50% in migration time and costs.

- Minimizes project execution, commissioning, and startup hours.

- Technological upgrade with new features:

- Touch HMI with intuitive process visualization.

- Adaptable communications with any high-level system.

- Access from remote engineering stations.

- Integration with OPC and potential embedded OPC.

- Adaptability to new plant safety requirements.

Local or Remote Migration

To ensure a successful migration, CPC carries out a 4-phase procedure:

- Phase 1: Extraction of the program from the controller. You can choose between 2 methods:

Traditional Extraction

Connecting the communication cable between the controller and the computer.

Remote extraction

Accessing the controller via wireless communication protocols.

- Phase 2: Translation and analysis of the program by reverse engineering.

- Phase 3: Implementation of the algorithm in the new equipment.

- Phase 4: Testing of the program by dynamic process simulation. Both programs (the original and the migrated one), are tested together to confirm that their functionalities are identical.

CPC Compact Solution Video

Video showcasing real footage of the CPC Compact Solution

| Design Flexibility | |

|---|---|

| General Information | |

| Structure | Lightweight anodized aluminum (6060-T5) with high corrosion resistance. |

| Mounting |

|

| Power Supply | 24 V DC; 120/220 V AC. |

| I/O Cards |

Allows up to 12 cards in the main CPU rack, selectable among:

|

| Digital Inputs/Outputs |

|

| Analog Inputs/Outputs |

Different signal types:

|

| Distributed Periphery | Possibility to incorporate up to 32 additional remote I/O cards via Profinet. |

| Screen | Touch HMI panel with various sizes from 4” to 20”. |

| Storage | HMI with data logging capability for up to 2 years for 20 signals. |

| Connectors | Rear panel fully compatible with existing connectors or adapted terminal blocks for quick connection. |

| Communications |

Ethernet

RS-485

Wireless

|

| Accessibility | Screen with FTP connection for remote access from engineering equipment on the same network. |

| OPC | Option to run an OPC on screen to integrate communications. |

| Additional Features | |

| Redundancy |

Option to include full redundancy in:

|

| Support | Immediate on-site or remote support. |

After-Sales Service

- Immediate support for problem resolution.

- After-sales service available in Spanish or English.

- Spare parts supply guaranteed for over 20 years.

- Remote Service Option.

- Implementation of new features.

- Screen updates.

Compromiso con el futuro

By choosing our solution, companies will not only effectively address current challenges related to controller obsolescence but also ensure continuous access to long-term technical support and spare parts.

This strategic approach not only mitigates risks but also guarantees the operational continuity of their facilities, ensuring optimal and sustainable performance for their plants in the future.

Download

Contact CPC Engineering

Would you like to know more information about our engineering services and solutions?

Contact a specialist!