Optimization of Control Systems on the FPSO BW-Adolo

Project Description

CPC Engineering has completed the second phase of the optimization and improvement project for the FPSO BW-Adolo unit, focusing on control loop tuning and the optimization of gas supply in the critical systems of the facility.

In the first phase of the project, a thorough review of the existing documentation and control systems of the FPSO was carried out. As part of this first phase, CPC Engineering was responsible for evaluating and adjusting the controls implemented in the PLC systems, using dynamic simulators at their offices to ensure maximum precision and effectiveness.

During this second phase and intervention, the CPC Engineering team, in collaboration with FPSO personnel, has worked on implementing improvements to the pressure controller settings. These improvements were essential for optimizing the fuel gas supply to the boiler, significantly reducing consumption by increasing the use of available natural gas at the facility.

Another key aspect of the project has been the adaptation of the controls to maximize the fuel gas supply to the boiler system, ensuring efficient and sustainable operation. CPC Engineering also provided comprehensive support during the commissioning of a new gas compressor, adjusting the control systems to ensure reliable and stable operation.

Additionally, detailed adjustments were made to the pressure control loops for the three-phase separators, improving operational stability and allowing for a faster and more precise response to variations in process conditions.

The work to optimize and improve efficiency on the FPSO BW-Adolo has been planned to be completed in various phases, which will continue to be implemented in the near future.

Project Details

Client

BW Offshore Adolo

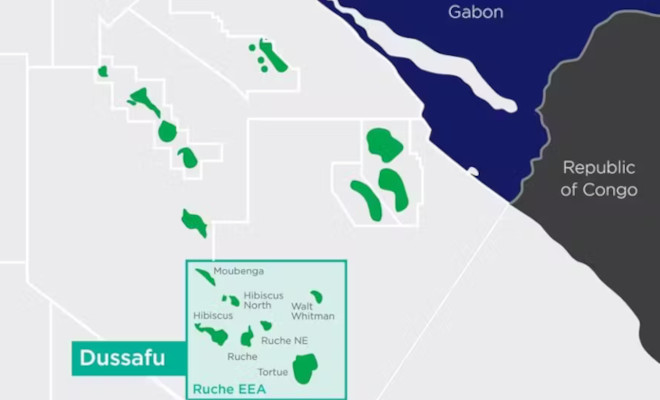

LocationGabon

Period2023-24